|

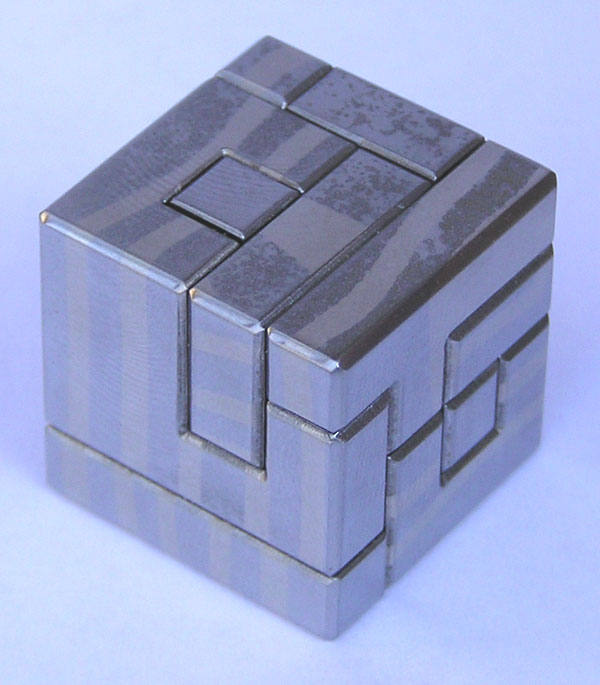

forged and pattern welded by Scott Lankton |

Starting with layers of steel and nickel; the strips are welded to a holding bar.

History Damascus steel was a term used by the Crusaders (AD 1095-1270) to describe the metal hot-forged by swordsmiths in the Middle East and first encountered by Europeans traders in the Syrian capital of Damascus. The Middle Eastern metalworkers were famous for their ability to hammer and temper bars of wootz steel into multi-layered metal blades. Damascus steel was especially valuable because it combined hardness with elasticity; it would bend but not break during combat and offered legendary sharpness. A legend told by 19th century English writer Sir Walter Scott told of a Damascus blade that could slice a falling silk scarf in half in midair. Perhaps, these blades helped Islamic armies repel European crusaders with inferior weapons. Modern research has shown that trace amounts of vanadium, chromium, manganese, cobalt, and nickel, impurities present in Middle Eastern carbon steel contributed to it's hardness and it's flexible nature.

|